Class-approved drone inspections for ships - UTM + Close-up without scaffolding

ORBIDRON executes drone-based Ultrasonic Thickness Measurement (UTM) and Remote Inspection Techniques (RIT) for cargo holds/tanks, ballast tanks, voids, cofferdams, and deck structures—delivering Class-aligned reporting with minimal disruption.

Certified service supplier for Drone & Manual UTM

Reduce staging, confined-space entry, and time lost in port/yard windows—without compromising reporting quality.

-

01

Efficiency without compromise.

Drone inspections remove the need for confined-space entry, scaffolding, and rope access—reducing risk. -

02

Keep the vessel moving.

Drone-enabled UTM supports faster inspections of tanks and holds—a major efficiency gain during tight port or yard windows. -

03

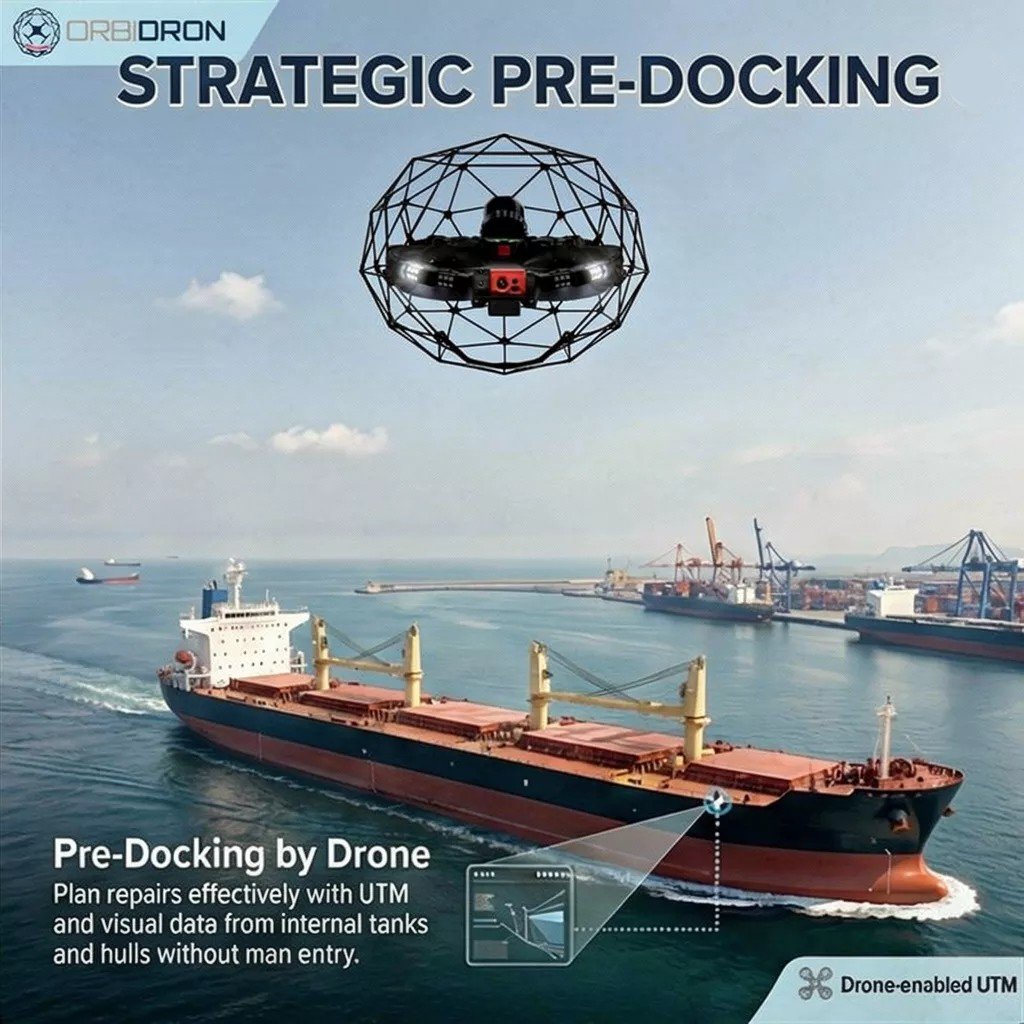

Shorter dock stay starts before docking.

Pre-docking drone inspections help lock steel renewals and coatings worklists in advance—reducing rework, change orders, and downtime. -

04

Class-aligned reporting, ready for review.

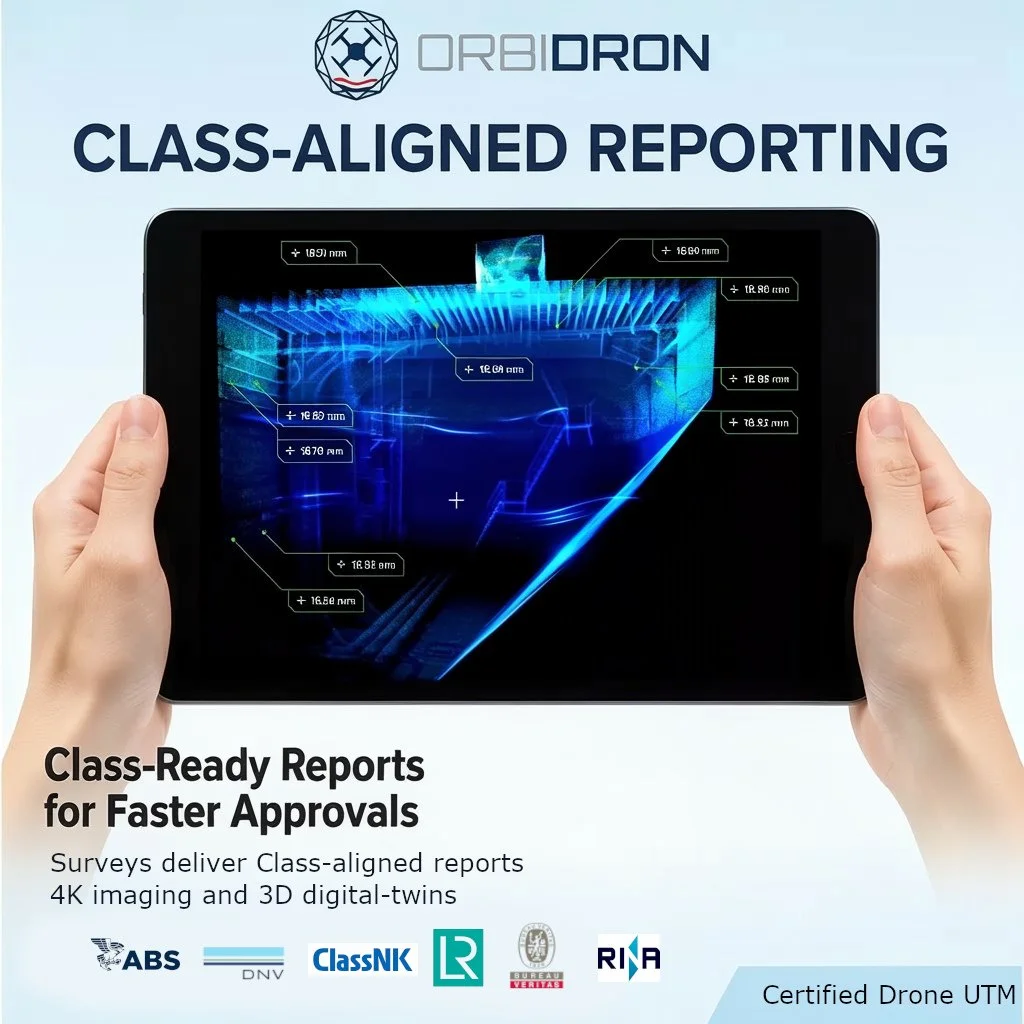

ORBIDRON delivers structured, Class-ready reports combining annotated 4K visuals and UTM data—built to speed up surveyor review and close-out.

What We Inspect

ORBIDRON applies a hybrid inspection workflow for Class surveys scopes to maximize efficiency while reducing dependency on scaffolding/rope access.

Drone-based Close-up and UTM Support

Close-up inspection of elevated/overhead structures, stiffeners, brackets, and critical details

Remote visual documentation (4K photo/video) linked to a structured defect register

Full UTM support in hard-to-reach and confined locations

Use of calibrated thickness gauges (drone-mounted) and certified personnel (pilots/UTM technicians)

Conventional Manual UTM

Manual UTM in easily accessible areas

Use of calibrated thickness gauges and certified personnel

Data integrity checks and cross-verification where required

Our Services

A. Class Survey Execution (UTM + Close-up)

Annual / Intermediate / Special / Renewal — hybrid Drone + Manual UTM to cover hard-to-reach + accessible areas.

B. Pre-Drydock Assessment (repair-driving intelligence)

Early condition visibility to support worklist, budgeting, and docking planning (defect register + thickness dataset + recommendations).

C. CAP / Condition Assessment

In-depth structural condition assessment and documentation beyond baseline Class, aligned to commercial/vetting needs.

D. Rapid Response / Damage Assessment

Collision/grounding or suspected structure failure—fast deployment and structured documentation.

Our Technology

Our cutting-edge Drone systems curry advanced UT payloads that provides highly accurate UT measurements. The LiDAR technology gives precise localization capabilities of all measurements and displays them in the 3D model –digital twin- of the asset.

With the software extension, the location-tagged UT measurements provide exceptional situational awareness, allowing us to easily track the completeness of the inspection.

Collision-tolerant caged platform for confined spaces

High-accuracy UT probes (2 / 5 / 7.5 MHz)

LiDAR-based localization to tag UTM points on a 3D model (digital twin)

16,000 lumens lighting for dark tanks/holds

Gas monitoring (LEL/O₂) as part of confined-space readiness